OUR PRODUCTS

Produk Panel Listrik

Semua produk panel listrik tegangan rendah yang diproduksi oleh PT ISTECH UTAMA mengacu ke dalam standard international IEC-61439 Panel Type Test dan IEC-601439 Panel Non Type Test.

- Panel LVMDB (Low Voltage Main Distribution Board) 90%

- Panel Kapasitor Bank 75%

- Panel PKG (Panel Kontrol Genset) 92%

- Panel MCC (Motor Control Center) 78%

- Panel SDP (Sub Distribution Panel) 85%

- Panel Penerangan 90%

STANDART PRODUCT

Standard karakteristik Produk Panel Listrik

| STANDARD KARAKTERISTIK | MAIN SWITCHBOARD | DISTRIBUTION BOARD |

|---|---|---|

| Type | Indoor | Indoor/Outdoor |

| Standard | IEC 61439-1/2 DAN IEC 60439-1/2 | IEC 61439-1/2 DAN IEC 60439-1/2 |

| No Phase | 3 Phase | 3 Phase |

| No Pole | 4 Pole | 4 Pole |

| Frequency | 50 Hz | 50 Hz |

| Tegangan Tertinggi Equipment | 400 V | 400 V |

| Main Busbar | Max 6300 A, CU 99,99% ex Import | Max 6300 A, CU 99,99% ex Import |

| Form Segregasi | Form 1 s/d 3B | Form 1 s/d 3B |

| Index Proteksi | IP30 s/d IP 65 | IP30 s/d IP 65 |

| Incoming/Outgoing Kabel Entry | Top/Bottom | Top/Bottom |

| Kontruksi Kabinet | 2mm Plat Hitam, Semi Knockdown, Metal Enclosed | 2mm Plat Hitam, Semi Knockdown, Metal Enclosed |

| Warna | Light Grey RAL 7032,Powder Coating, Texture/Glossy | Light Grey RAL 7032,Powder Coating, Texture/Glossy |

| Komponen | Schneider, ABB, Siemens, Mitsubishi, LS, Terasaki, Fuji | Schneider, ABB, Siemens, Mitsubishi, LS, Terasaki, Fuji |

| Dimensi | H2000 x W900 X D1200 | H800 x W300 x D300 |

Standard karakteristik Produk Box Panel

| STANDARD KARAKTERISTIK | BOX PANEL TIPE WALL MOUNTING |

|---|---|

| Type | Indoor/Outdoor |

| Index Proteksi | IP30 s/d IP 65 |

| Konstruksi Kabinet | 2mm Plate Hitam Finished Powder Coating |

| Warna | Ligth Grey RAL 7032, 5y7/1, RAL 7035, 5y8/1.5 Powder Coating, Texture/Glossy |

| Dimensi | H1000 x W800 X D250 |

Flow Of Process

Step Of Process

STEP 1 : DESIGN

- Design Box dan schematik wiring

- Raw material

STEP 2 : SHEET METAL WORKSHOP

- Metal plate marking, cutting, punching, welding dan grinding

- Inspeksi dimensi dan kualitas Box/Enclosure untuk di painting

- Proses Treatment

- Primary & Powder coating

- Oven drying

- Inspeksi warna dan tekstur cat

STEP 3 : ELECTRICAL WORKSHOP

- Setting busbar

- Pemasangan komponen

- Wiring dan marking kabel

- Test isolasi

- Simulation test control dan indicator

- Switching test

STEP 4 : WAREHOUSE

- Packing

- Delivery

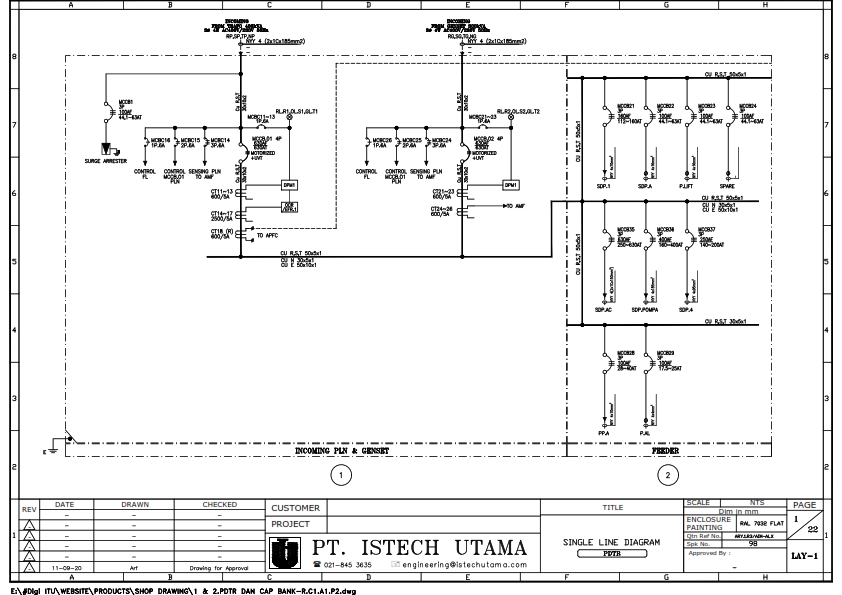

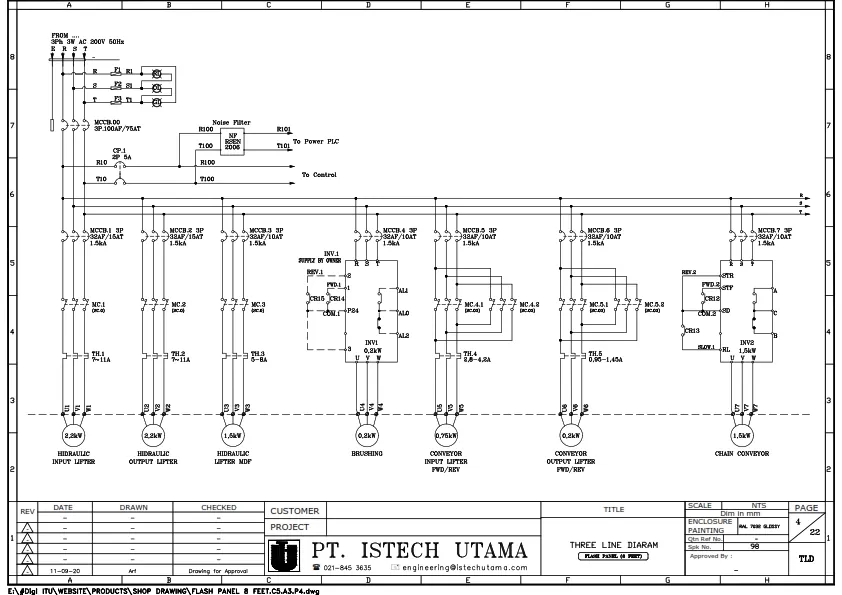

Shop Drawing

FACTORY PRODUCTION FACILITES

| NO | FACILITES |

|---|---|

| 1 | Mesin Hydraulic Press Brake |

| 2 | Mesin Hydraulic Shear Merk SMS |

| 3 | Mesin hydraulic punch |

| 4 | Mesin diesel Honda 4PK |

| 5 | Mesin press kabel skun hydraulic |

| 6 | Mesin tekuk tembaga hydraulic |

| 7 | Mesin pon untuk tembaga manual |

| 8 | Mesin bor duduk besar merk GENERAL |

| 9 | Mesin bor duduk kecil merk WEST LAKE |

| 10 | Mesin bor tangan merk MAKITA |

| 11 | Mesin kompressor merk Hitachi |

| 12 | Pemadam kebakaran merk PEACOCK 11 kg |

| 13 | Mesin las merk Panasonic |

| 14 | Meger digital merk Kyoritsu |

| 15 | Paint shop powder coating |

| 16 | Mesin gurinda |

| 17 | Multi meter digital |

| 18 | Analyzer - HYBT |

| 19 | Clamp ampere |

| 20 | Tool set / Safety Tool Kit |

| 21 | Safety Gloves High Voltage |

| 22 | Safety Belt High Voltage |

| 23 | Safety Screw |